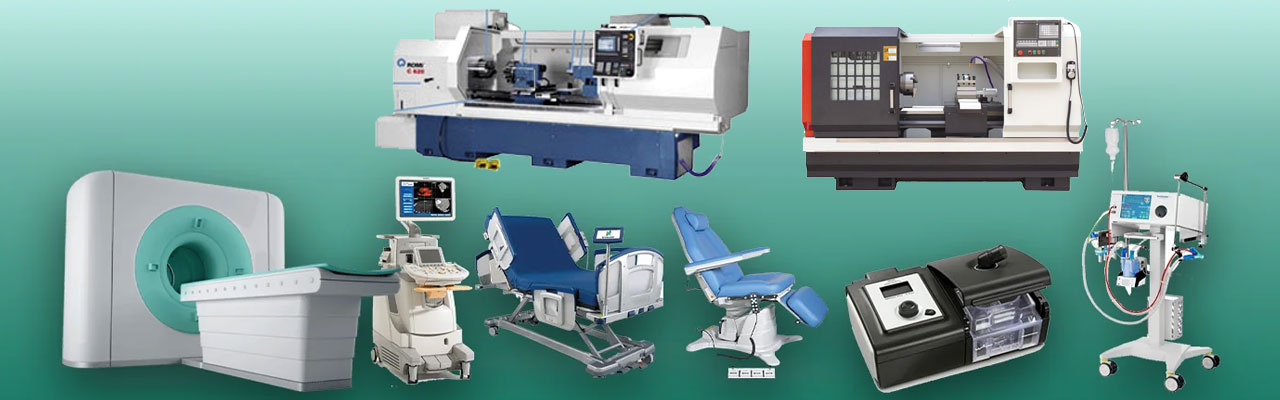

medical equipments & machineries

Medical equipments

Owing to their dimensional accuracy, perfect finish and high durability, these products are highly demanded in the market.

Our products are rigorously checked on various quality parameters for ensuring the flawlessness of the entire product range. Owing to their superior performance, high durability and optimum functionality, these products are extremely demanded in hospitals, primary health centers and nursing homes.

Machineries

CNC turning machines are machine tools that rotate a bar of material, allowing the cutting tool to remove material from the bar until the desired product is remaining. It is primarily used to manufacture parts that are cylindrical in nature.

The material itself is secured to, and rotated by, the main spindle, while the cutting tool can be moved along multiple axis. These machines can be capable of facing, threading, knurling, drilling, boring, reaming, and taper turning. Horizontal CNC turning machines are more common, but vertical machines utilize gravity.

CNC machining is far better than manual machining for a few specific reasons:

• Programming a CNC to complete a job creates a consistent and accurate cut to ensure product quality. It can be repeated over and over in the exact same manner.

• The cost of hiring a person to manually machine parts at scale is far more expensive than having a machine do it, as a machine will not tire, does not need lunch breaks, and can, theoretically run 24/7.

• CNC turning can churn out hundreds and hundreds of parts while retaining a consistent end product.